Contents

- 1 WASTE MANAGEMENT IN IRAN WETRO GMBH

- 2 AGENDA

- 3 TARGET

- 4 MISSION/VISION IRAN

- 5 PORTFOLIO

- 6 PRODUCT PORTFOLIO

- 7 „MBT VS. INCINERATION“

- 8 TARGET

- 9 INNOVATIVE WASTE MANAGEMENT

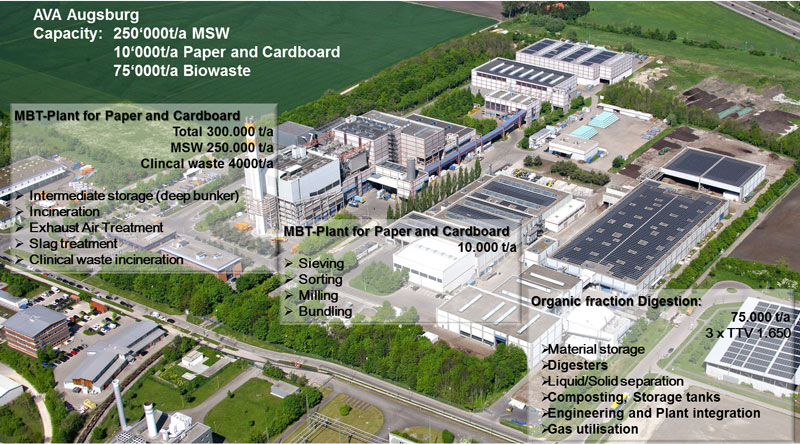

- 10 REFERENCE „AUGSBURG – BEST PRACTICE“

- 11 INNOVATIVE WASTE MANAGEMENT (IWM)

- 12 THÖNI DIGESTION SYSTEMS, OUTSTANDING TECHNOLOGY

- 13 THÖNI AGITATORS – SLOWLY RUNNING – LOW OPEX

- 14 THÖNI DRY DIGESTION TECHNOLOGY , „MOST ROBUST DESIGN – WORLDWIDE“

- 15 POSSIBLE FEEDSTOCK

- 16 TREATMENT OF ORGANIC DIFFERENT TYPES OF ORGANIC WASTE

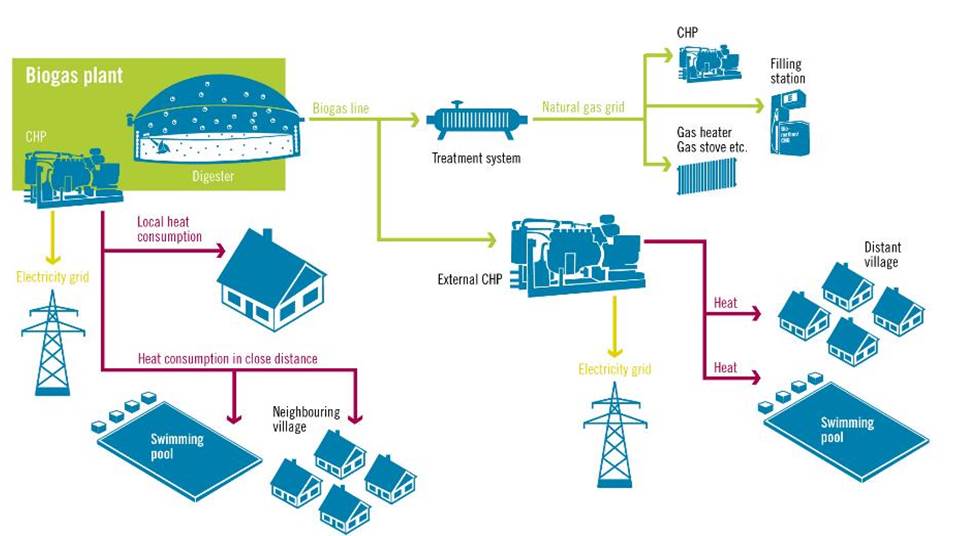

- 17 POSSIBLE USE OF BIOGAS

- 18 BIOGAS UTILISATION – BIOGAS UPGRADING TO CNG

- 19 BIOGAS CONCLUSION

- 20 RDF-PELLETS – BACKGROUND

- 21 RDF-PELLETS – PROCESS PHILISOPHY

- 22 RDF-PELLETS – CALORIFIC VALUE

- 23 RDF-PELLETS – PELLET CHARACTERISTICS

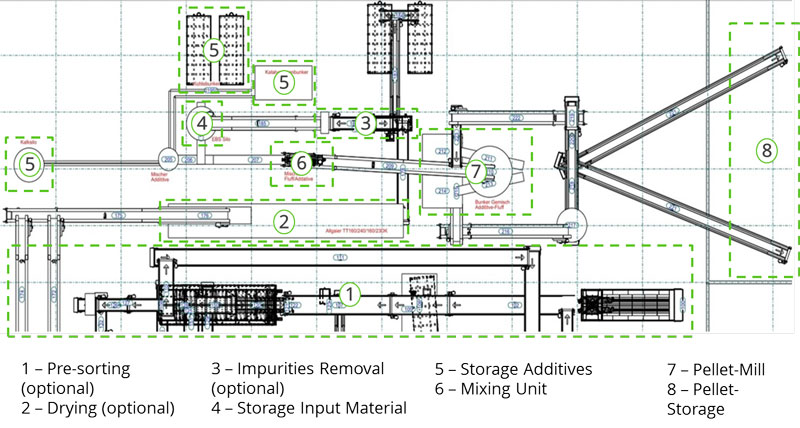

- 24 RDF-PELLETS – ENGINEERING FOR 40‘000T/A

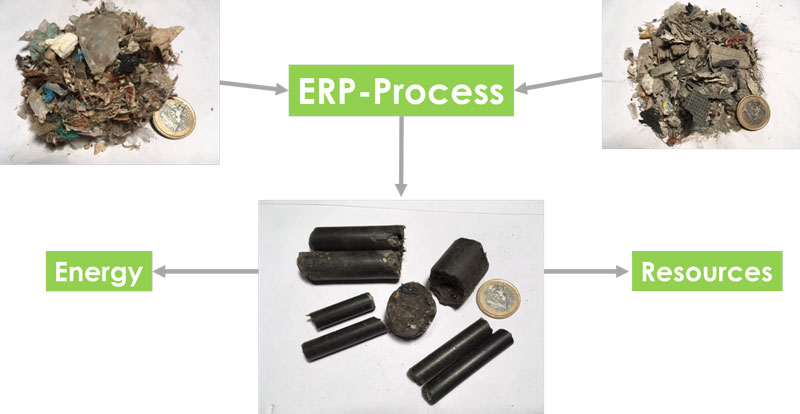

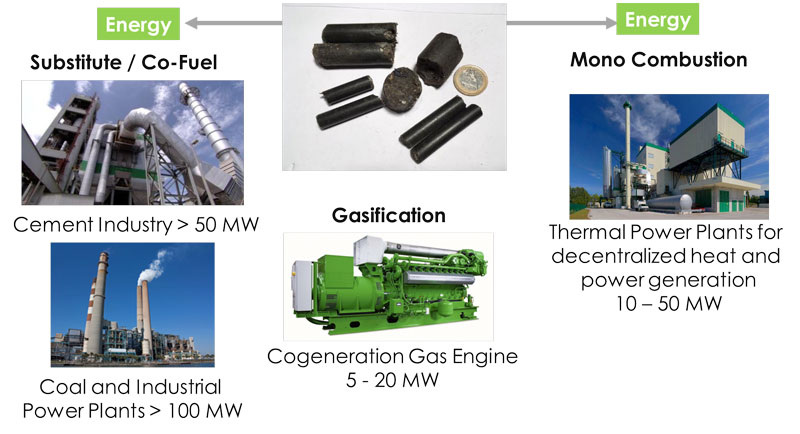

- 25 „WASTE TO RESOURCES“ WITH RDF-PELLETS

- 26 „POSITIVE CO2 FOODPRINT“

- 27 „INCINERATION VS. IWM“

WASTE MANAGEMENT IN IRAN

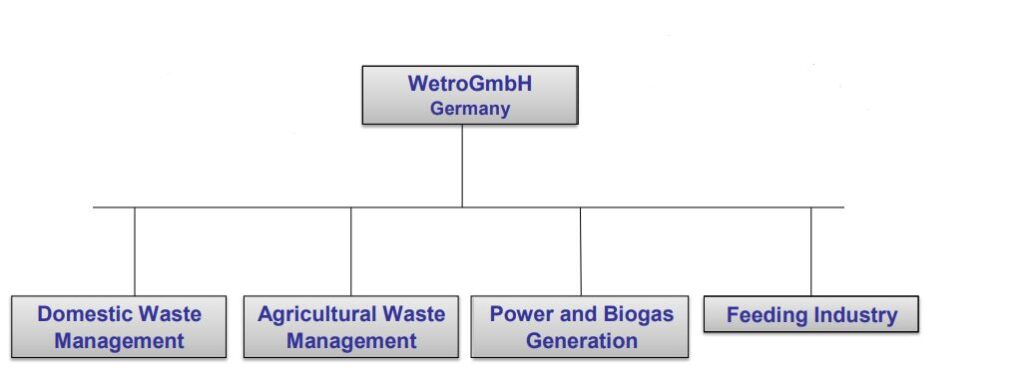

WETRO GMBH

WetroGmbH

Experience from one source

Sorting • Recycling • Biogas • RDF-Pellets • Incineration • Decentralized Power Generation

AGENDA

- Introduction of WetroGmbH

- Mass Incineration vs. Mechanical Biological Treatment

- Innovative Waste Management

- Dry-Fermentation Process

- Energy and Resource Pellets

- Innovative Waste Management

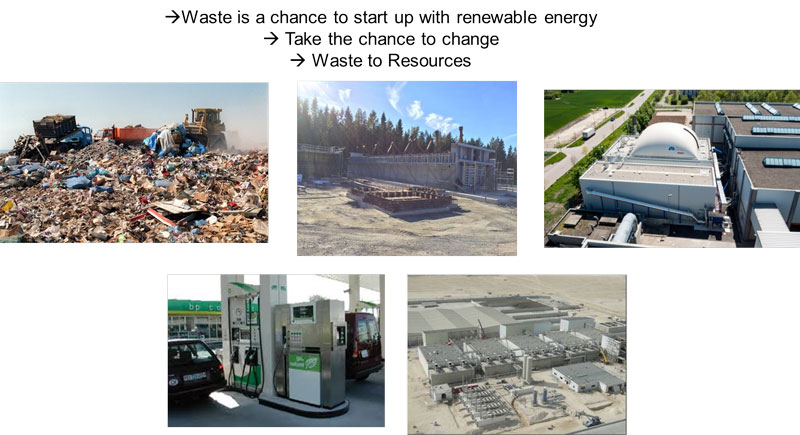

TARGET

We follow the principle of cascade utilisation or

multiple use of resources on different levels.

We see waste as a resource that should be used sustainably and efficiently for saving raw-materials and for reducing greenhouse gas emissions.

We implement the most efficient and innovative technologies for our waste management solutions

MISSION/VISION IRAN

Together with our local cooperation partners we are the specialist for innovative waste management concepts.

We offer solutions for recycling, MSW sorting, biogas production from waste, biogas purification to methane quality and decentralised power generation. We follow the principle: «waste to resources»

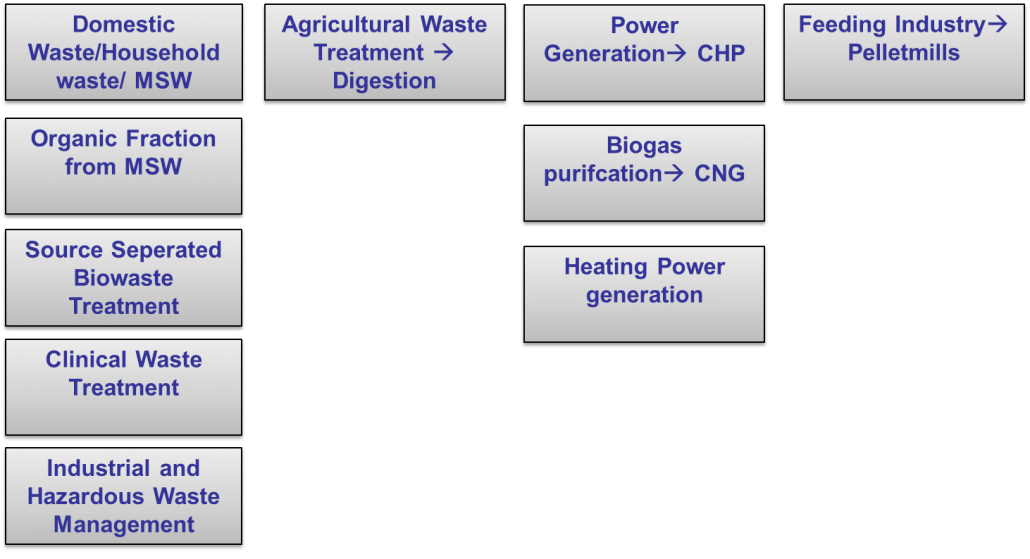

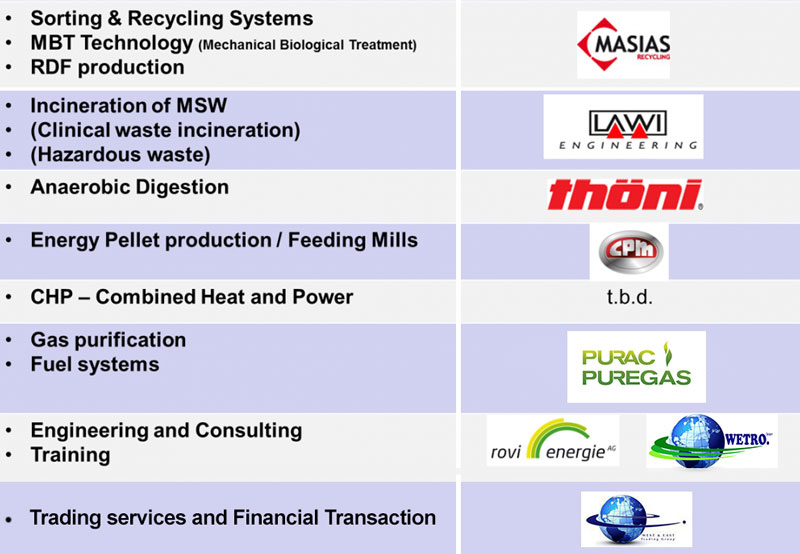

PORTFOLIO

PRODUCT PORTFOLIO

„MBT VS. INCINERATION“

Mass Incineration

Centralized energy production

- Waste to energy 1.0 (low efficiency)

- Complex flue gas treatment

- Energy demand (oil, gas) for incineration of wet materials

- Low employment rates

MBT-Biogas-Energy Pellets

Decentralized energy production

- Waste to energy 2.0 (high efficiency)

- Recycling (plastics, metals, etc.)

- RDF-pellet production

- Biogas production from MSW organic fraction

- Higher employment rates

- Higher local value creation

TARGET

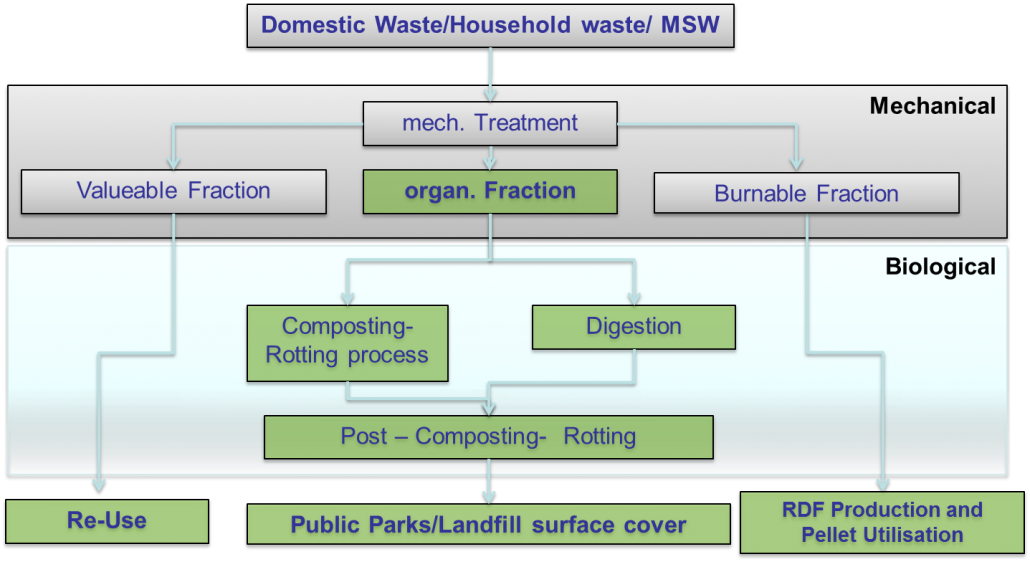

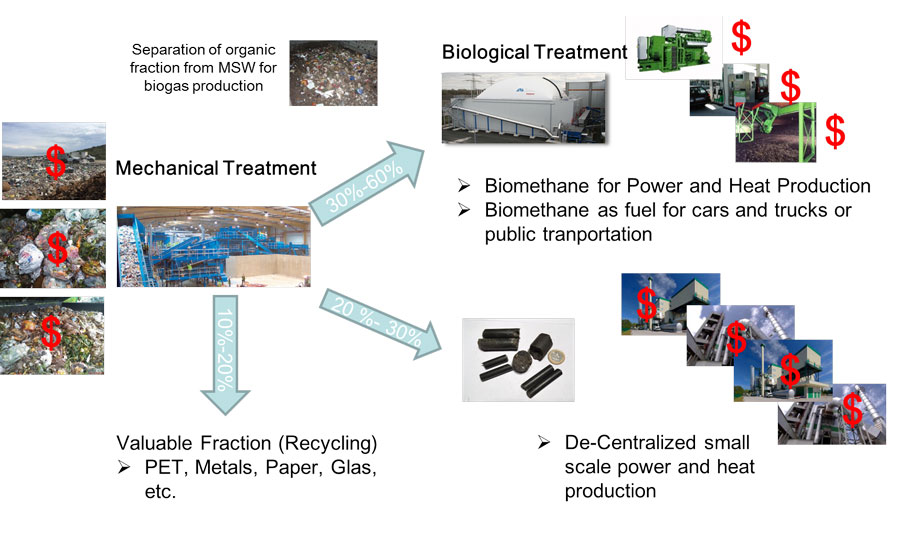

INNOVATIVE WASTE MANAGEMENT

REFERENCE „AUGSBURG – BEST PRACTICE“

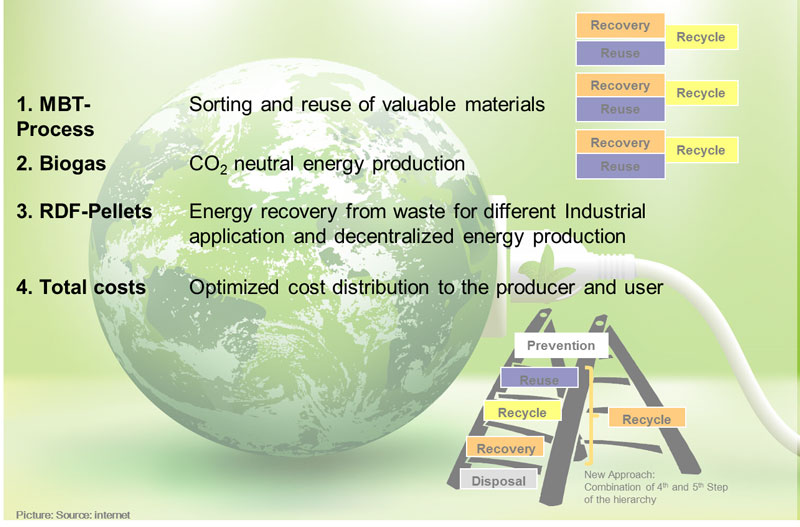

INNOVATIVE WASTE MANAGEMENT (IWM)

1.MBT – Process

Seperation of recycable materials

Seperation of non-recycables

Prodcution of RDF pellets

Seperation of organic fraction from MSW

2.Selling of RDF-pellets to different industrial sectors

Generation of electricity and process heat for heating and cooling (absorption chillers)

- Production of biogas from MSW organic fraction Generation of energy and/or vehicle fuel

- Power Generation by Non-recycable waste Generation of electricity and process heat for heating and cooling (absorption chillers)

THÖNI DIGESTION SYSTEMS, OUTSTANDING TECHNOLOGY

Thöni provides „Biowaste to Energy“ technology for private waste management companies and municipalities

for sustainable agriculture

for innovative waste management companies

for ecologically aware municipalities

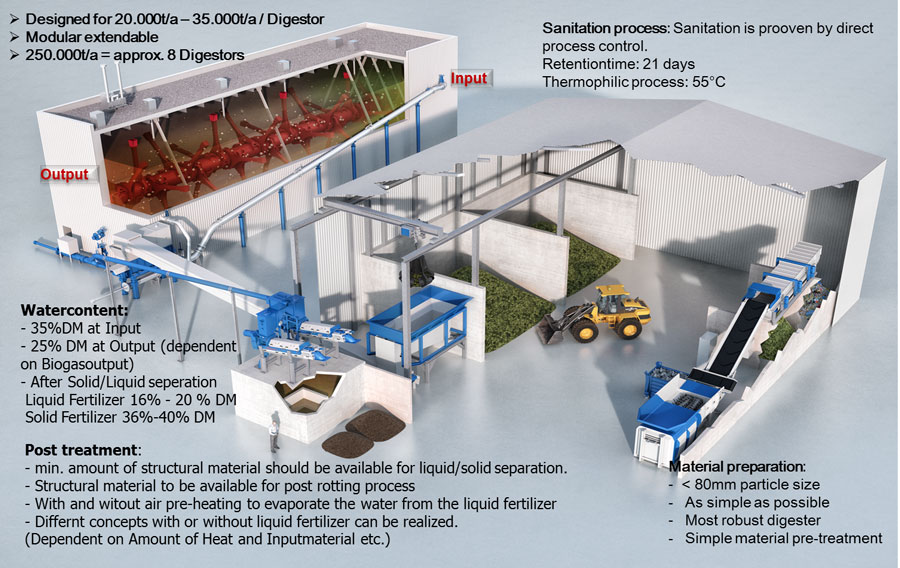

THÖNI AGITATORS – SLOWLY RUNNING – LOW OPEX

Thöni‘s engineering is well known for the

„robust digester design“ and thus „highest reliability“

for save operation

and highest availability

THÖNI DRY DIGESTION TECHNOLOGY , „MOST ROBUST DESIGN – WORLDWIDE“

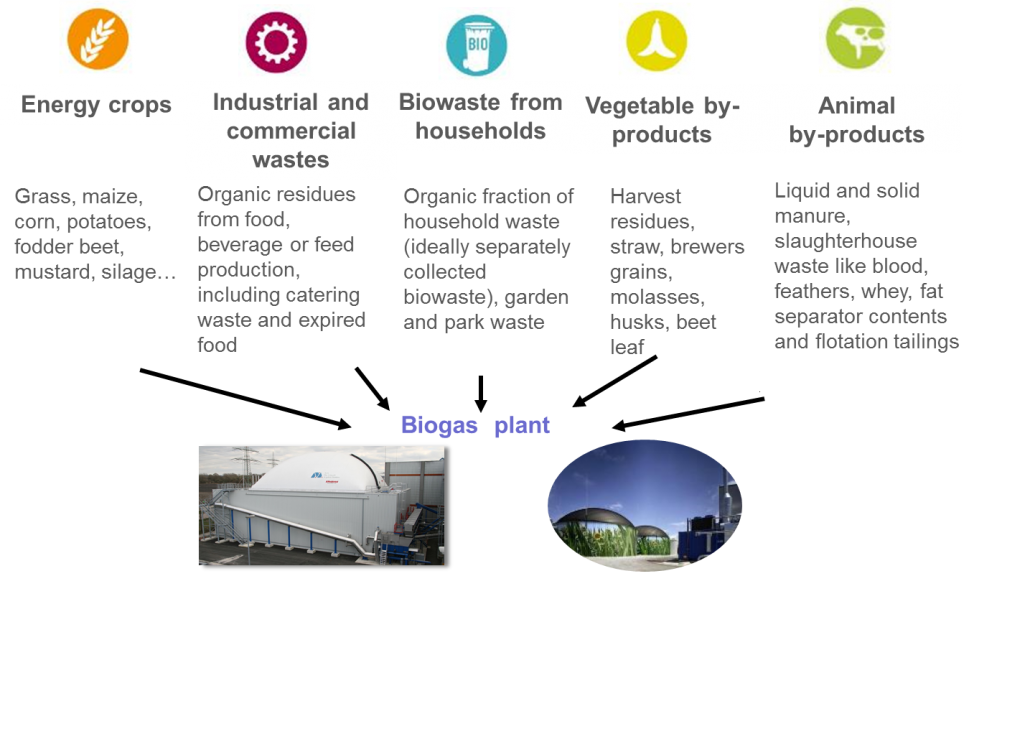

POSSIBLE FEEDSTOCK

TREATMENT OF ORGANIC DIFFERENT TYPES OF ORGANIC WASTE

Different treatment processes with extensive experience available

Dry fermentation, Wet fermentation, Batch, Plug Flow Fermentaiton

More than 400 built biological waste treatment plant (Biogas plants)in Germany

Experience since more than 25 years in anaerobic digestion

Waste and process experience essential due to undefined Input Material

POSSIBLE USE OF BIOGAS

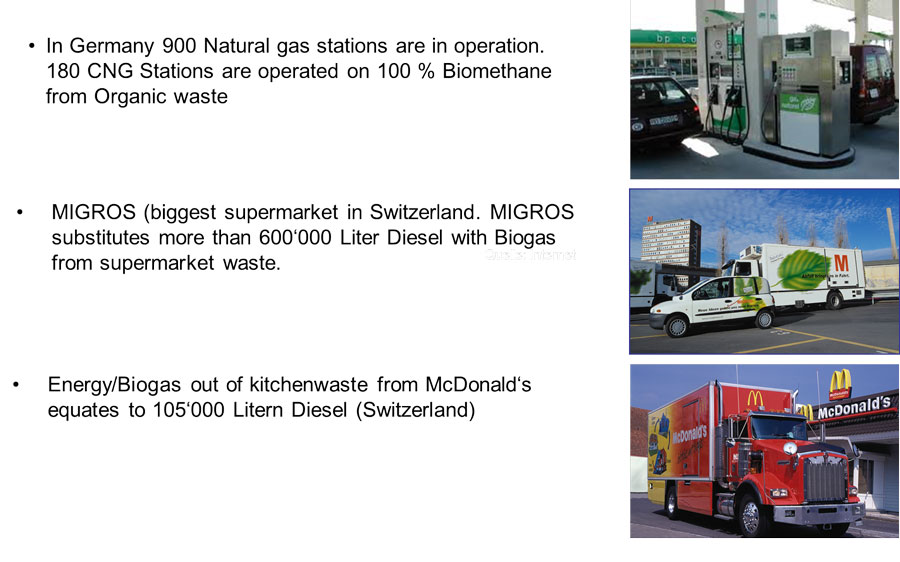

BIOGAS UTILISATION – BIOGAS UPGRADING TO CNG

BIOGAS CONCLUSION

RDF-PELLETS – BACKGROUND

- Decentralized energy production reaches efficiency > 90%

- Every MWh produced by pellets saves oil and gas for export

- Pre-sorting of waste can be adapted to local demand for recyclables

- Example: Paper can be recycled locally or used for the pellets

- Smaller scale decentralized plants create more jobs than big incinerations

- Highest value creation by combination of:

- Recycling à Resources

- Pellet Production à Decentralized electrical and thermal power generation

- Biogas Production à Transport fuel (carbon neutral)

- Composting à Fertilizer

RDF-PELLETS – PROCESS PHILISOPHY

„Production of a compact, storable and non-toxic solid fuel from waste”

- Compaction by pelleting at factor of 5 – 10

- Pellets are easy to transport and can be stored without time limitation

- No up-front removal of pollutants (chlorine, sulphur etc.) required

- Pollutants are fixed in the ashes and not present in the flue gas

- Utilization of pellets in decentralized power plants < 50 MW

- Utilization of pellets for syngas production possible

- No timely or areal link of waste treatment and waste utilization required

–Pellets can be produced at place A and can be used several month later at place B

RDF-PELLETS – CALORIFIC VALUE

RDF-PELLETS – PELLET CHARACTERISTICS

| Characteristic | Value | Unit |

| Density: | 1,6 – 1,8 | g/cm³ |

| Bulk Density: | 850 – 1.200 | kg/m³ |

| Combustion Point: | < 150 | °C |

| Ignition Point: | < 350 | °C |

| pH-Value: | < 7,50 | |

| Heating Value: | 15.000 – 20.000 | kJ/kg |

| Water Content: | 8 – 9 | % |

| Ash Content: | 15 – 25 | % |

| Total Sulfur: | 0,2 – 0,4 | % |

| Volatile Compounds: | ca. 40 | % |

| Ash Melting Point: | 1.000 – 1.050 | °C |

| Range of Grit: | D: 10 – 25, L: 20 – 40 | mm |

RDF-PELLETS – ENGINEERING FOR 40‘000T/A

„WASTE TO RESOURCES“ WITH RDF-PELLETS

„POSITIVE CO2 FOODPRINT“

„INCINERATION VS. IWM“

„Thank you for your attention“

Your partner and engineering consultant for

environmental friendly, sustainable and

«intelligent waste management»

WETRO GmbH

Postfach 100220

63702 Aschaffenburg

Germany

Mobile: +491715304851/WhatsApp

E-Mail: [email protected]